Cat Hydraulic Excavators are the most versatile machines on the jobsite, ranging from small landscaping projects to large surface extraction mines—and everywhere in between.

SYSTEM OVERVIEW

Hydraulic excavators are extremely versatile machines used for a variety of purposes, from grading to mass excavation to demolition work. A hydraulic excavator's main work tool is a bucket, but these machines can also be equipped with hydraulic couplers to pick up a variety of tools.

Balancing your desired productivity/penetration with the wear life of your system is critical. Excessive wear material can reduce productivity and increase fuel burn. Cat hydraulic excavator buckets and G.E.T. are designed as a balanced system to increase life while minimizing drag.

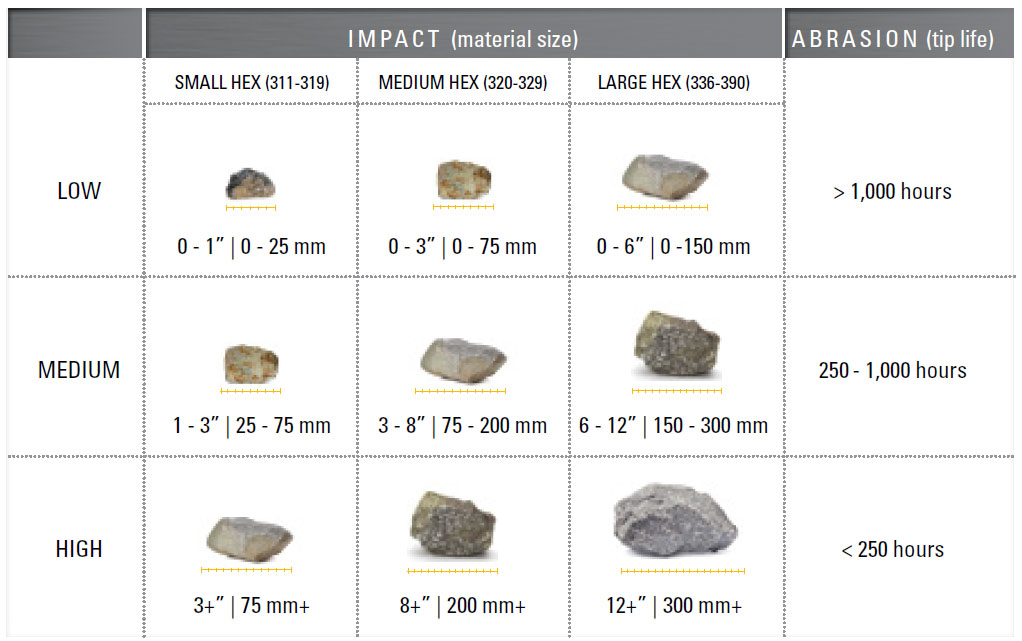

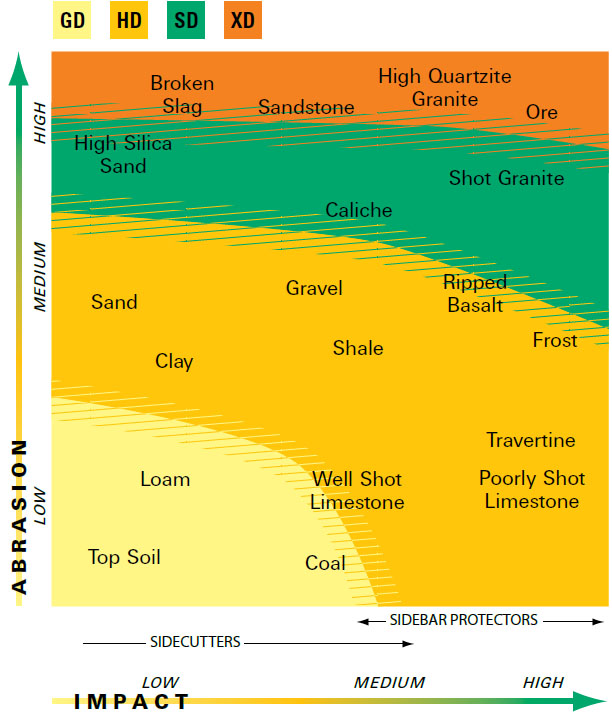

TIP SELECTION GUIDE

Even though bucket tips come in many shapes and sizes, you don't have to be an expert to choose the right ones. Use the chart below to determine if the material you're digging in is high, medium or low impact and abrasion—then find the balance you need among these three factors:| Description |

|---|

| 1. STRENGTH The ability to withstand digging and penetrating shocks and high breakout forces. |

| 2. PENETRATION The ability to penetrate tough material when it's tightly compacted, rocky or frozen. |

| 3. WEAR LIFE The ability to withstand wearing, scouring and abrasive action of the material being handled. |

K SERIES TIP & ADAPTER SYSTEM

MAXIMUM PRODUCTIVITY MEETS HAMMERLESS RETENTION.

Looking for a vertical retention tip and adapter system that stays sharper, changes easier and holds tighter? Choose the K Series system's twist-on design and vertical retainer, which together provide reliable retention and easy installation and removal.

| Name | Description |

|---|---|

| IMPROVE YOUR PRODUCTIVITY | Low-profile shape provides optimal sharpness, penetration and digging ability throughout the tip life. |

| EXTEND LIFE | More wear material can effectively be used before the tips are changed, adding 10-15% more usable life. |

| INCREASE DURABILITY | The tip and adapter fit together precisely to reduce tip movement and adapter wear. |

| STAY SAFE & REDUCE MAINTENANCE COSTS | One-piece vertical retainer allows for easy installation and removal. |

| SIMPLIFY INSTALLATION | Rails on both sides of the adapter and a twist-on design hold the tip in place, allowing for quicker installation. |

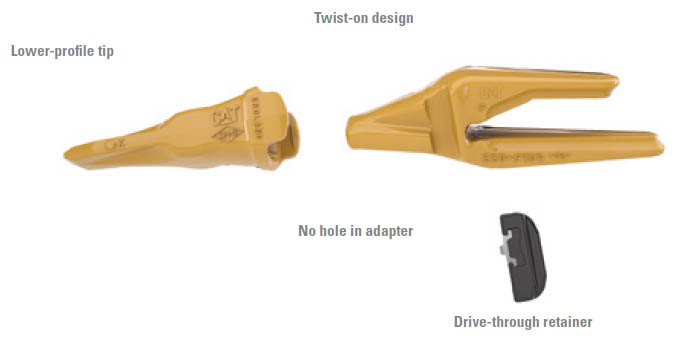

K SERIES DRIVE-THROUGH TIP & ADAPTER SYSTEM

The drive-through system is for K80-K100 adapters and tips.

INSTALLATION & REMOVAL

It's safe and easy—just use a standard pry tool and follow this three-step process:

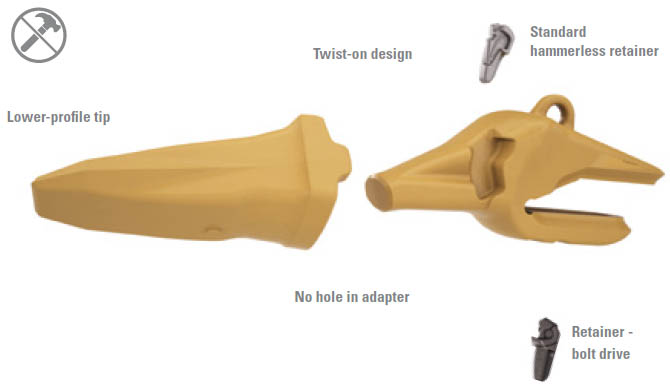

K SERIES HAMMERLESS TIP & ADAPTER SYSTEM

The hammerless system is for K110-K170 adapters and tips.

INSTALLATION & REMOVAL

It's safe and easy—just use a standard pry tool and follow this three-step hammerless process:

K SERIES TIP OPTIONS

Below are the tip shapes best suited for the wide range of jobsite conditions performed by hydraulic excavators. We also offer additional K Series tips more commonly used with wheel loaders. Your Cat dealer can help you choose the one that offers the right balance of penetration and wear life for your application.

| Image | Description | Option |

|---|---|---|

| EXTRA DUTY » Extra Duty and Extra Duty Abrasion Resistant Material (A.R.M.)* tips include approximately 60% more wear material in the tip body. The A.R.M. wears around the profile to increase penetration. | A.R.M. |

| GENERAL PURPOSE » General Purpose tips are symmetrical and the baseline for other tip styles. All wear comparisons are to the General Purpose tip unless otherwise noted. | |

| WIDE » Wide tips are used to maintain smooth trench floors and in low-abrasion, easy-to-penetrate material. | |

| PENETRATION PLUS » Penetration Plus tips feature 25% more wear material and a leading edge with 25% less cross-sectional area. They self-sharpen as they wear. | |

| PENETRATION » Penetration tips are ideal for densely compacted materials. They feature a leading edge with 60% less cross-sectional area— allowing for maximum penetration—and a single center rib that self-sharpens as it wears. These tips are available with A.R.M.* | A.R.M. |

| SPIKE » Spike tips are used to achieve maximum penetration. They are typically used in cohesive material and stay sharp during the life of the tip. | |

| DOUBLE SPIKE » Double Spike tips are used in the corner positions with the spike tips for hard-to-penetrate, fracturable materials. |

*Abrasion Resistant Material (A.R.M.) is a welding process that bonds very hard tungsten carbide particles to Cat G.E.T. to create a protective shield over the component. Typically, the A.R.M. process doubles wear life—and can last even longer in some applications.

K SERIES ADAPTER OPTIONS

All K Series adapters feature rails on both sides of the nose for a twist-on design that stays in place during installation.

MACHINE COMPATIBILITY

| ESCAVADORA | LIGAÇÃO | CLASSE DE TAMANHO |

|---|---|---|

| 315 | N/D | K80, K90 |

| 318 | N/D | K80, K90 |

| 320 | Reach | K80, K90 |

| Mass Excavation | K90, K100 | |

| 324 | Reach | K90, K100 |

| Mass Excavation | K100, K110 | |

| 329 | Reach | K90, K100 |

| Mass Excavation | K100, K110 | |

| 336 | Reach | K100, K110 |

| Mass Excavation | K110, K130 | |

| 349 | Reach | K110, K130 |

| Mass Excavation | K130 | |

| 374 | Reach | K150 |

| Mass Excavation | K170 | |

| 390 | Reach | K150 |

| Mass Excavation | K170 |

J SERIES TIP & ADAPTER SYSTEM

SIDE-PIN SECURITY WHEN YOUR APPLICATION DEMANDS IT.

Great performance and proven reliability over time—that's what you get with this classic horizontal retention system, a staple in the construction and mining industries.

| Name | Description |

|---|---|

| BOOST YOUR VERSATILITY | Industry-standard side-pinned design performs across a variety of applications. |

| ENHANCE YOUR RELIABILITY | Weld-on adapters offer excellent retention. |

| IMPROVE SAFETY & MAINTENANCE TIME | Ability to retrofit means you can use the hammerless CapSureTM system. |

J SERIES TIP & ADAPTER SYSTEM

INSTALLATION & REMOVAL

Simply use the standard pin and retainer system—and make removal even easier with our Tip Pin Remover tool.*

| Image | Description |

|---|---|

| 1. Place the tool on the tip and align the extractor with the pin. |

| 2. Strike the tool with a hammer until the pin is removed. |

| 3. Place the tool over the tip (A), locate the pin in the hole of the holder (B) and strike the tool (C). |

*J550 and smaller use the pin removal tool. Consult your dealer for larger systems.

J SERIES TIP OPTIONS

Below are the tip shapes best suited for the wide range of jobsite conditions performed by hydraulic excavators. We also offer additional J Series tips more commonly used with wheel loaders. Your Cat dealer can help you choose the one that offers the right balance of penetration and wear life for your application.

| Image | Description | Option |

|---|---|---|

| HEAVY DUTY LONG » Heavy Duty Long and Heavy Duty Abrasion Resistant Material (A.R.M.)* tips include approximately 60% more wear material in the tip body. The A.R.M. wears around the profile to increase penetration. | A.R.M. |

| LONG (GENERAL PURPOSE) » Long tips are symmetrical and the baseline for other tip styles. All wear comparisons are to the Long tip unless otherwise noted. | |

| WIDE » Wide tips are used to maintain smooth trench floors and in low-abrasion, easy-to-penetrate material. | |

| PENETRATION PLUS » Penetration Plus tips feature 30% more wear material and 25% less cross-sectional area. They self-sharpen as they wear. | |

| PENETRATION » Penetration and Penetration A.R.M.* tips are ideal for densely compacted materials. They feature a leading edge with approximately 50% less crosssectional area and a single center rib for strength—allowing for maximum penetration. | A.R.M. |

| SPIKE » Spike tips are used to achieve maximum penetration. They are typically used in cohesive material and stay sharp during the life of the tip. | |

| SPIKE CORNER » Spike Corner tips can be used in the corner position with sharp center tips. | |

| DOUBLE SPIKE » Double Spike tips are used in the corner positions with the spike tips for hard-to-penetrate, fracturable materials. |

*Abrasion Resistant Material (A.R.M.) is a welding process that bonds very hard tungsten carbide particles to Cat G.E.T. to create a protective shield over the component. Typically, the A.R.M. process doubles wear life—and can last even longer in some applications.

GENERAL DUTY TIPS

General Duty tips offer a reliable, competitively priced parts option for small to medium-sized excavators operating in low to medium impact conditions. Tips are available in the J250-J460 size range.

General Duty tips are:

» A match if you require quality and long wear

» Designed to fit J Series adapters, reducing risky fit-ups

» Backed by the standard Caterpillar warranty against breakage under normal, recommended operation in low to medium impact applications

J SERIES MACHINE COMPATIBILITY

| Excavator | Linkage | Size Class |

|---|---|---|

| 312 | N/D | J250, J300 |

| 315 | N/D | J300, J350 |

| 318 | N/D | J300, J350 |

| 320 | Reach | J300, J350, J400 |

| Mass Excavation | J400, J460 | |

| 324 | Reach | J400, J460 |

| Mass Excavation | J460, J550 | |

| 329 | Reach | J400, J460 |

| Mass Excavation | J460, J550 | |

| 336 | Reach | J460, J550 |

| Mass Excavation | J550 | |

| 349 | Reach | J550 |

| Mass Excavation | J550 | |

| 374 | Reach | J600 |

| Mass Excavation | J600 | |

| 390 | Reach | J600 |

| Mass Excavation | J700, J800 |

| Image | Description |

|---|---|

| LONG » Most versatile shape with good balance of penetration, strength and abrasion resistance. Standard shape for most applications. |

| HEAVY DUTY LONG » Use on larger machines where greater strength is required. More wear material for higher abrasion environments. |

| PENETRATION PLUS |

HAMMERLESS TIP & ADAPTER SYSTEM FEATURING CAPSURE RETENTION

LOSE THE HAMMER, NOT THE FLEXIBILITY.

Simplify bucket tip replacement with hammerless CapSure retention. These tips are matched to side-pin adapters, allowing the flexibility to use our conventional pin retention if your application demands it.

| Name | Description |

|---|---|

| LOWER OPERATING COSTS | Side-pin retrofit design used on J-style adapters means the pin is reusable. |

| ENHANCE JOBSITE SAFETY & MAINTENANCE TIME | A 3/4-inch retainer lock requires no special tools and allows for hammerless installation and removal. |

| CHANGE OUT TIPS QUICKLY & EASILY | Positive stop is cast into the tip to prevent over-rotation—just turn 180 degrees to lock or unlock. |

| SPEED UP YOUR INSTALLATION TIME | Tip and retainer are one system, so there's no special assembly or extra pieces. |

HAMMERLESS TIP & ADAPTER SYSTEM FEATURING CAPSURE RETENTION

INSTALLATION & REMOVAL

It's fast, easy and safe with the CapSure locking system— just follow these four simple steps:

| Image | Description |

|---|---|

| 1. Insert pin and washer into the adapter hole. |

| 2. Slide the tip onto the adapter. |

| 3. Tighten 180° into the locked position with a 3/4" ratchet. |

| 4. Remove by loosening 180° to the unlocked position. |

CAPSURE TIP OPTIONS

We offer four CapSure tip options designed for a range of jobsite conditions. Your Cat dealer can help you choose the one that offers the right balance of penetration and wear life for your application.

| Image | Description |

|---|---|

| HEAVY DUTY ABRASION » Heavy Duty Abrasion tips are ideal for high-abrasion applications like sand, gravel and shot rock. They have the maximum amount of wear material— approximately 145% more—and the tip base features 35% more surface area than Heavy Penetration tips. |

| HEAVY PENETRATION » Heavy Penetration tips are ideal for high-impact, hard-to-penetrate materials. They feature approximately 120% more material in the high wear area as well as a sharp spade design with 70% less cross-sectional area on the leading edge than Heavy Duty Abrasion tips. |

| HEAVY DUTY » Heavy Duty tips are the baseline for other tips. All wear comparisons are to the Heavy Duty tip unless otherwise noted. |

| PENETRATION PLUS |

MACHINE COMPATIBILITY

| Excavator | Linkage | Size Class |

|---|---|---|

| 336 | Reach | N/D |

| Mass Excavation | J550 (Retrofit) | |

| 349 | Reach | J550 (Retrofit) |

| Mass Excavation | J550 (Retrofit) | |

| 374 | Reach | J600 (Retrofit) |

| Mass Excavation | J700 (Retrofit) | |

| 390 | Reach | J600 (Retrofit) |

| Mass Excavation | J700 (Retrofit), J800 (Retrofit) |

BASE EDGE SYSTEMS

FASTEST INSTALLATION TIMES IN THE INDUSTRY.

Cat base edge systems go through a series of carefully controlled manufacturing processes to deliver maximum strength, durability and long life. They come completely welded and assembled, dramatically shortening your installation and replacement time.

| Name | Description |

|---|---|

| INCREASE DURABILITY | A consistent heat-treat process maximizes strength and resists abrasion. Shot blasting removes impurities that can cause inclusions on a weld, and controlled cooling reduces the chance of stress points. |

| SAVE INSTALLATION & REPLACEMENT TIME | Butterbead is applied to the back side of the base edge and the top strap of the corner adapter, so you can weld the edge onto the bucket without preheating. |

| OPTIMIZE MACHINE PERFORMANCE | Base edges are designed by Caterpillar engineers for optimal performance on specific machines. |

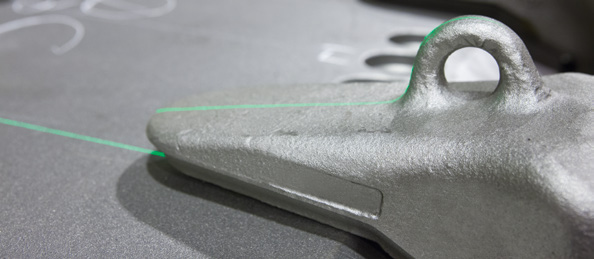

GET MORE ACCURACY

Base edge replacement involves replacing a base edge assembly, which includes adapters welded in from the factory, or replacing a bolt-on cutting edge (BOCE) base edge, which comes with factory-drilled holes for bolt-on G.E.T. Choose from three shapes (base edge for BOCE, straight and spade base edge assemblies) to get the right protection for your application.

| Image | Description |

|---|---|

| BOLT-ON CUTTING EDGE |

| STRAIGHT |

| SPADE |

Lasers place the adapters within 0.1 mm of specifications.

BUTTERBEAD BASE EDGE ASSEMBLY

DURABLE PROTECTION COMBINED WITH SHORTER INSTALLATION TIMES.

The protection you need, with no preheating required—that's what you get with butterbead weld prep. This technique, which involves applying a layer of weld to a heat-treated, higher hardness part, makes it possible to weld a base edge to a bucket without preheating the hardened part. Choose from two shapes (straight and spade) on cutting edges thicker than 50mm and three levels of build to get the right protection for your application.

| Name | Description |

|---|---|

| SPEED UP YOUR INSTALLATION TIME | Weld prep eliminates the need for preheating, shortening edge installation time by 30-50%. |

| GET MORE DURABILITY | Base edges have the proper butterbead weld because it is applied in the factory. |

BASE EDGE END PROTECTION (BEEP)

PROTECT YOUR CORNERS—WITHOUT CUTTING THEM.

Reduce base edge end wear and subsequent corner adapter weld erosion with our BEEP design. It makes adapter replacement on the edge much easier when it's time to rebuild the base edge assembly. BEEPs are available in a wide array of thicknesses and angles to fit 336-390 hydraulic excavators.

| Name | Description |

|---|---|

| BOOST YOUR UPTIME | Through-hardened Rc ~45 (Br ~3.0) weldable steel is easily installed in the shop or the field. |

| EXTEND LIFE | Extended base edge end protects adapter corner welds. |

| SPEED UP INSTALLATION | Height and bevel are matched to the base edge, so there's no additional fabrication. |

SIDE & EDGE PROTECTION

MAINTAIN YOUR PERFORMANCE EDGE.

Protect your bucket's structural integrity with sidebar protectors and shear blocks or increase penetration and performance with side cutters.

» Sidebar Protectors

» Side Cutters

» Half Arrows

» Top Covers

» Cutting Edges

» Weld-On Edge Shrouds

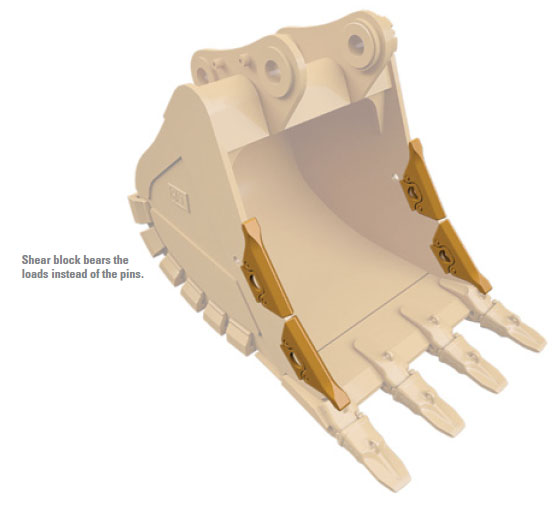

SIDEBAR PROTECTORS

PROTECT YOUR BUCKET'S STRUCTURAL INTEGRITY WITH SIDEBARS AND SHEAR BLOCKS.

| Name | Description |

|---|---|

| INCREASE YOUR UPTIME | Shear block protects the pin from extreme loads and breakage, helping ensure sidebar protector retention. |

| CUT YOUR MAINTENANCE COSTS | Sidebar protector protects the bucket edge. |

SIDECUTTERS

Improve your bucket's performance while protecting your sidebars.

| Image | Description |

|---|---|

| GENERAL PURPOSE SIDECUTTER |

| HEAVY DUTY SIDECUTTER » For tough digging conditions. » More wear material. » Covers more of the sidebar for enhanced protection of the bucket. » Scalloped profile improves bucket penetration and machine performance. |

| STRIKEOFF SIDECUTTER » Half arrow shape to provide better penetration than bare bucket. » Protects the lower bucket sides and corners. » For use in moderate-to-light conditions. » Can be stacked for more protection. |

BOLT-ON HALF ARROWS, TOP COVERS, CUTTING EDGES & WELD-ON SHROUDS

Protect your investment in buckets and base edges with these flexible components. Half arrows allow for a smooth transition of material over the base edge to protect the leading edge. Top covers complement the half arrows to protect the base edge fully. Modular edge shrouds are designed to fit any bucket configuration and extend the life of your excavator bucket edge assembly.

| Name | Description |

|---|---|

| SIMPLIFY MAINTENANCE | Individual pieces that protect the edge can be changed independently. |

| ENHANCE DURABILITY | Half arrows cover the leading edge for smooth material transition. |

| BOOST YOUR UPTIME | Top cover reduces wear on weld joints. |

BUCKET SELECTION GUIDE

We offer four standard bucket durability categories suitable for any application. Each category is based on the bucket's intended durability when used in the recommended application and material.

| Image | Description |

|---|---|

| GENERAL DUTY |

| SEVERE DUTY » For a wide range of impact and abrasion conditions including mixed dirt, clay and rock. Example: Digging conditions where Penetration Plus tip life ranges from 400 to 800 hours. » HD buckets are a good “center line” choice, or starting point, when application conditions are not well known. |

| EXTREME DUTY » For a wide range of impact and abrasion conditions including mixed dirt, clay and rock. Example: Digging conditions where Penetration Plus tip life ranges from 400 to 800 hours. » HD buckets are a good “center line” choice, or starting point, when application conditions are not well known. |

| EXTREME DUTY |

CHOOSING THE RIGHT DURABILITY.

Choosing the wrong bucket can easily reduce production and increase operating costs by 10-20% or more. It can also cause unnecessary wear and fatigue for both machine and bucket. Contact your local Cat dealer for more detailed information on choosing the right excavator, bucket and work tool attachment combinations to meet your application needs.

CAT DEALER & BUCKET MANAGEMENT

CHOOSING CAT G.E.T. IS EASY.

Your Cat dealer makes it easy to choose the right G.E.T. for your machines and applications. In addition to a broad portfolio of products, your dealer offers the sales, service and technical support you need to keep productivity high and operating costs low. Trust your Cat dealer to:

| Name | Description |

|---|---|

| MAXIMIZE PRODUCTIVITY | Buckets and G.E.T. products are designed to meet your application requirements, rather than simply fit onto your machine. |

| IMPROVE PERFORMANCE | Get the most out of your bucket and G.E.T. with expert advice that helps you lower costs and reduce unscheduled maintenance. |

| SIMPLIFY MAINTENANCE | Tailored G.E.T. systems simplify your maintenance. We develop solutions that fit your expectations, including custom products. |

| MANAGE WEAR | Intuitive Cat Inspect bucket inspection programs help you monitor how your G.E.T. system is wearing so you can adapt to changes in application and operation. |

Talk to your Product Support Representative or G.E.T. specialist today to learn how they can help you simplify your bucket management by using Cat Inspect.

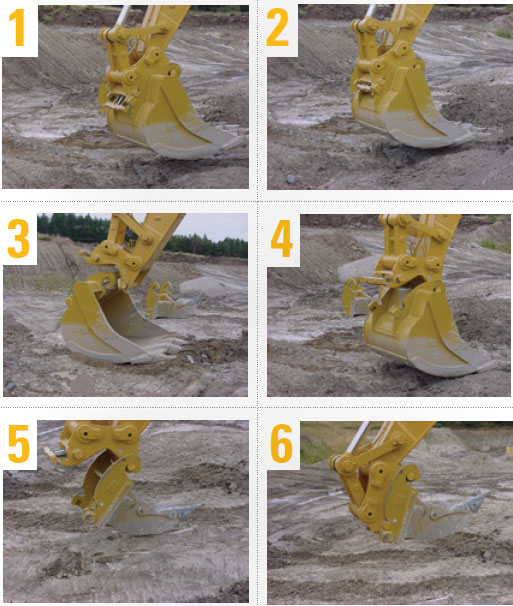

HYDRAULIC EXCAVATOR (HEX) RIP AND LOAD

Using rippers mounted on large HEX is a cost-effective alternative to blasting in quarries and site development. In site development, rippers on smaller excavators and backhoe loaders can readily deal with asphalt, caliche and frozen ground.

| Name | Description |

|---|---|

| IMPROVE YOUR PRODUCTIVITY | Increase productivity by adding efficiency and flexibility to your operation. |

| EXTEND LIFE | A through-hardened hammerless wear tip and shank protector extend wear life. |

| INCREASE DURABILITY | Upsized, hammerless adapters and tips accommodate higher loads and abrasion, while edge segments and top covers protect your base edge. |

RIPPER-TO-BUCKET CHANGES ARE MADE HYDRAULICALLY IN LESS THAN 35 SECONDS.

This gives the operator complete flexibility to continually adjust ripping, sorting and loading work.

| Name | Description |

|---|---|

| SIMPLE CHANGES | Pull material down and change bucket quickly and easily. |

| BLAST FREE | Ripper allows you to work without blasting in areas with unstable land or sound regulations. |

TAKE ADVANTAGE OF THESE TECHNOLOGIES TO IMPROVE THE PRODUCTIVITY AND PROFITABILITY OF YOUR APPLICATION.